Burnie Group’s Operational Excellence offering helps organizations improve performance by eliminating inefficiencies, reducing costs, and building smarter, more resilient operations. We work with clients to streamline processes, improve execution, and embed a culture of continuous improvement using a Lean-based approach. Our solutions drive measurable results including improved resource utilization, increased productivity, and higher stakeholder engagement.

Our operational excellence offering

Our offering focuses on achieving exceptional operational performance across every part of an organization. It involves aligning strategy, people, processes, and technology to deliver consistent, high-quality outcomes while minimizing waste and increasing efficiency. Organizations that achieve operational excellence are better equipped to meet customer expectations and sustain long-term growth.

Operational excellence is driven by the process pillar of Burnie Group’s Target Operating Model framework. We assess and redesign key business processes to ensure they are clearly defined, effectively governed, and tightly aligned to strategic objectives. By mapping current-state workflows, identifying root cause issues, and applying leading process improvement techniques, we help organizations build more agile, integrated, and value-driven operations.

At Burnie Group, our operational excellence offering is grounded in a Lean approach, a proven methodology for driving sustainable improvement. We work with organizations to identify inefficiencies, eliminate barriers to performance, and design future-state operations that are streamlined and scalable.

A core component of Lean methodology includes identifying and eliminating non-value-added activities through the 8 types of waste framework, which targets:

Our approach

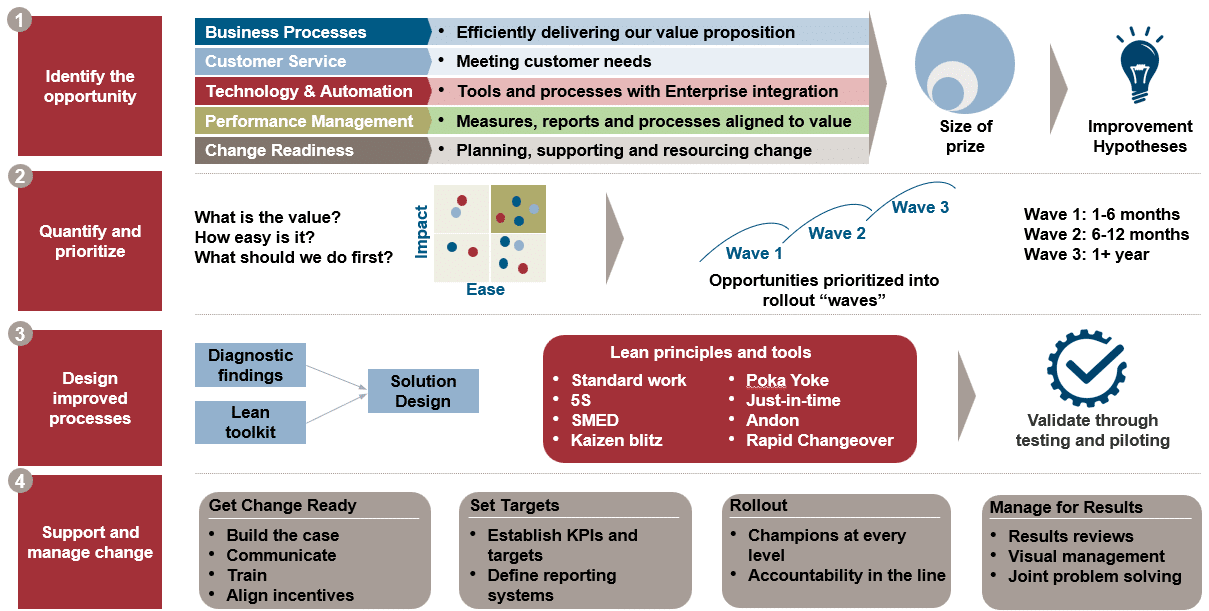

Burnie Group applies a four-step approach to help organizations achieve operational excellence and ensure improvements are practical, sustainable, and aligned to strategic priorities.

1. Identify the Opportunity

We begin by assessing where and how your operations can improve across five key dimensions: business processes, customer service, technology and automation, performance management, and change readiness. This helps uncover inefficiencies, gaps, and opportunities to better deliver value to your customers and stakeholders.

2. Quantify and Prioritize

We evaluate each opportunity based on impact and ease of implementation to determine where to start and how to phase improvements. Initiatives are prioritized into rollout waves, ensuring your organization sees early wins while setting the stage for long-term success.

3. Design Improved Processes

Using diagnostic insights and Lean tools, we design solutions that are practical, scalable, and rooted in operational best practices. We validate proposed improvements through testing and pilot programs to ensure they deliver measurable results in real-world conditions.

4. Support and Manage Change

We help your organization get change-ready by aligning leadership, building internal champions, training teams, and defining clear KPIs. Our approach ensures strong execution and accountability through structured rollout, results tracking, and collaborative problem-solving.

Our Tools

Here are some tools we use to support our diagnostic:

DILO (Day in the Life Of)

- Observational tool to understand how employees spend their time throughout a typical workday to uncover inefficiencies, role misalignment, and improvement opportunities

Process Mapping

- Visual representation of workflows to identify bottlenecks, redundancies, and non-value-added steps

Spaghetti Diagram

- Physical workflow diagram that traces the movement of people, materials, or information to highlight layout inefficiencies and reduce wasted motion

5S Diagnostic

- Evaluation of workplace organization using the 5S principles (Sort, Set in order, Shine, Standardize, Sustain) to improve efficiency and work environment

Mystery Shopping

- Anonymous evaluation of services from a customer’s perspective to identify experience gaps and inconsistencies

Customer Journeys

- Mapping of end-to-end customer experiences across all channels and interactions to find pain points and improve overall experience and satisfaction

Shrink Analysis

- Review of inventory loss due to theft, damage, administrative errors, or process failures to reduce waste, improve controls, and minimize financial impact

Inventory Analysis

- Examination of inventory levels, turnover, and accuracy relative to demand to optimize inventory management and reduce carrying costs

Why choose Burnie Group

- Burnie Group brings extensive experience in driving operational excellence across sectors such as financial services, healthcare, and telecommunications. Our work helps organizations streamline processes, reduce costs, improve quality, and build a foundation for sustainable growth

- We specialize in applying Lean principles and practical diagnostic tools to uncover inefficiencies and design high-impact, scalable solutions

- We combine deep process improvement expertise with performance management, technology integration, and change management capabilities to deliver lasting transformation

- Our team has successfully led end-to-end operational transformations, from front-line functions to back-office operations—improving productivity, reducing error rates, and enhancing customer and employee experience

- Our proven track record includes helping clients achieve measurable results such as cycle time reductions, significant cost savings, and improved service levels through targeted and data-driven operational improvement programs

Learn more about how our operations excellence program can benefit your organization.

CONTACT US